Make chicken feed pellets formula:

For chicks aged 1-60 days, the following formula can be used:

| 62% corn, 10% bran, 17% soybean cake, 9% fish meal, 2% bone meal. |

| Or use: 60% corn, 10% bran, 22% soybean cake, 6% fish meal, 2% bone meal. |

Feed formula for growing and laying period

Growing period (61-120 days):

| 55% corn, 20% bran, 7% soybean cake, 5% cottonseed cake, 5% rapeseed cake, 5% fish meal, 2% bone meal, 1% shellfish meal. |

| Or use: 66% corn, 18% soybean cake, 11% sunflower seed meal, 3% fish meal, 1.5% bone meal, 0.5% salt. |

Egg-laying period: A variety of formulas can be used, for example:

Opening period:

| 72.00% corn, 10.0% soybean meal, 8.0% peanut kernel cake, 2.20% fish meal (domestic), 1.30% calcium hydrogen phosphate, 5.52% stone powder, 0.10% methionine, 0.11% lysine, 1.0% vegetable oil, 0.50% additives, 0.30% salt. |

Peak egg-laying period:

| 55.7% corn, 8.0% second-grade flour, 11.5% soybean meal, 8.0% peanut kernel cake, 4.0% fish meal (domestic), 1.2% calcium hydrogen phosphate, 7.7% stone powder, 0.10% methionine, 3.0% vegetable oil, 0.50% additives, 0.30% salt. |

Other egg-laying periods:

| corn 67.70%, soybean meal 8.0%, cottonseed cake 2.0%, peanut kernel cake 8.0%, fish meal (domestic) 3.0%, calcium hydrogen phosphate 1.20%, stone powder 7.2%, methionine 0.10%, lysine 0.05%, vegetable oil 2.0%, additives 0.50%, salt 0.30%. |

Homemade chicken feed formula

Some chicken farmers choose to make their own chicken feed to reduce costs and ensure balanced nutrition.

The formula of homemade chicken feed can include the following ingredients:

30-40 parts of soybeans, 80-90 parts of corn, 10-15 parts of rice bran, 3-5 parts of houttuynia cordata, 1-2 parts of isatis root, 3-4 parts of bupleurum, 1-2 parts of rhubarb, 2-3 parts of whitehead, 1-2 parts of verbena, 0.8-1 parts of astragalus polysaccharide, 0.5-0.8 parts of electrolytic multivitamin, 4-5 parts of wolfberry, 2-3 parts of Millettia reticulata.

These formulas can be adjusted to the specific growth stage and nutritional needs of the chicken to ensure that they provide enough protein, vitamins and minerals to promote healthy growth and egg production.

Necessary machines for make chicken feed pellets

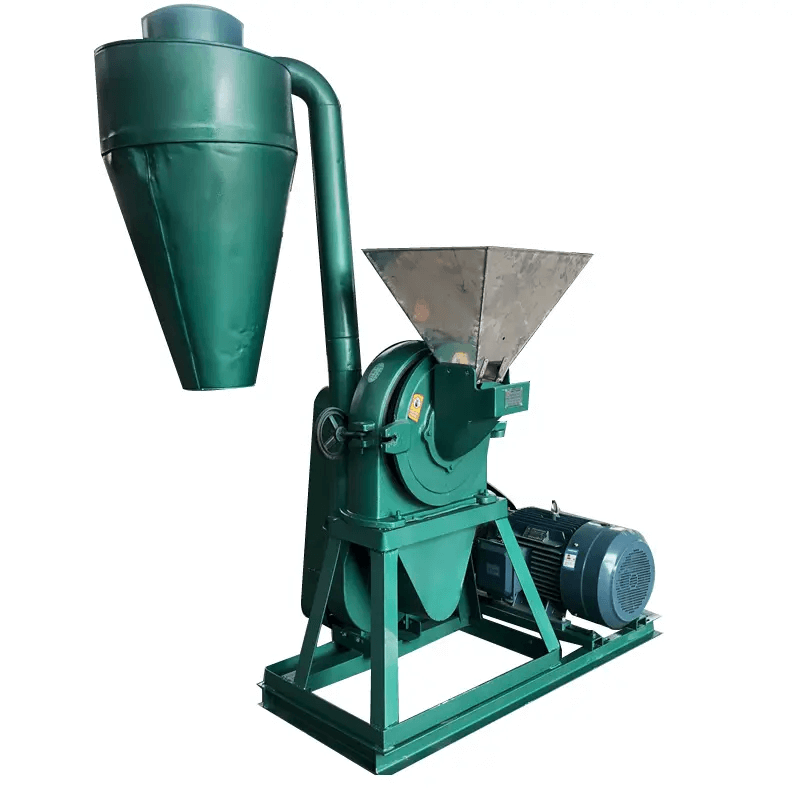

Feed crusher hammer mill

The crushing of feed raw materials is a very important link in feed processing. Crushing can increase the total surface area of raw material particles per unit mass, increase the solubility of feed nutrients in animal digestive fluid, and improve the digestibility of animals; at the same time, the small particle size of the crushed raw materials has a very important influence on the difficulty of subsequent processes (such as granulation) and the quality of the finished product; the smaller the crushing particle size, the more conducive it is to animal digestion and absorption, and the more conducive it is to granulation.

Different model can be choose according to needs, more details, please see: feed crusher mixer.

|

|

|

Mixing machine for all material

The function of a mixer is to mix various materials and additives evenly. There are generally three types of mixers to choose from.

- Stainless steel mixing tank (small capacity)

- Vertical mixer (with crushing function)

- Horizontal mixer (large capacity)

For more details, please check: feed crusher mixer.

|

|

|

|

Feed pellet machine

There are two types of flat die feed pellet machines:

- Fixed roller press

This feed pellet machine requires the material to be crushed before pelleting. With the same production capacity, the price is relatively low.

- Rolling roller press

This feed pellet machine can directly pelletize large pieces of material and complete the crushing during the extrusion process, saving time and effort.

The two flat die feed pellet machines also play a sterilizing role during operation. The maximum temperature is 75 degrees, which can kill your microbial strains without affecting the nutritional content of the feed.

The template and roller press of the pellet machine are high-alloy wear-resistant materials, with the characteristics of long service life, reasonable structure, firmness and durability.

More details, please see: animal feed pellet machine

|

|

|

|