1-2t/h Feed Production Line

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty

Pellet Production Line Characteristics

Pellet Production Line Industry Specification

| Capacity | 15 tons/hour |

Other characteristics

| Applicable industries | Manufacturing plant,Farm,For home use,Energy & production,Animal feed shop |

| Showroom location | No |

| Origin of goods | Henan,China |

| Weight | 1850 kg |

| Guaranteed | 1 year |

| Key Selling Points | High performance |

| Marketing type | New product 2020 |

| Equipment for production Test Report | Not available |

| Video OUTGOING-inspection | Given that |

| Main Components Warranty | 5 years |

| Main components | Gear,Gearbox,Engine,Bearing,Engine |

| State | New |

| Name | Songbai |

| Type | Granule feeding machine |

| Voltage | 380V |

| Size(L*W*H) | 860*420*1100mm |

| Application | Poultry Farm |

| Product name | Animal Feed Pellet Plant |

| Usage | Animal Poultry Livestock Pellet Making Machine |

| Function | Aniaml Feed Puffed Pellet Machine |

| Raw material | Wheat Bran Hay Grass Straw |

| After-sales Service Provided | Online Support |

| Keywords | Poultry Feed Processing Equipment |

| Capacity | 1-10TPH |

| Final product | Animal Feed Poultry Feed Mill |

| Processing Types | Livestock Feed Plant |

Packaging and delivery

| Packaging details | Customized

|

Order fulfillment period

| Quantity (pcs.) | 1 – 3 | > 3 |

| Estimated time (in days) | 15 | Subject to approval |

Made to order

| Emblem to order | Min. order : 1 pc. |

| Individualized packaging | Min. order : 1 pc. |

| Graphic settings | Min. order : 1 pc. |

For more information on custom manufacturing, please send a message to the supplier

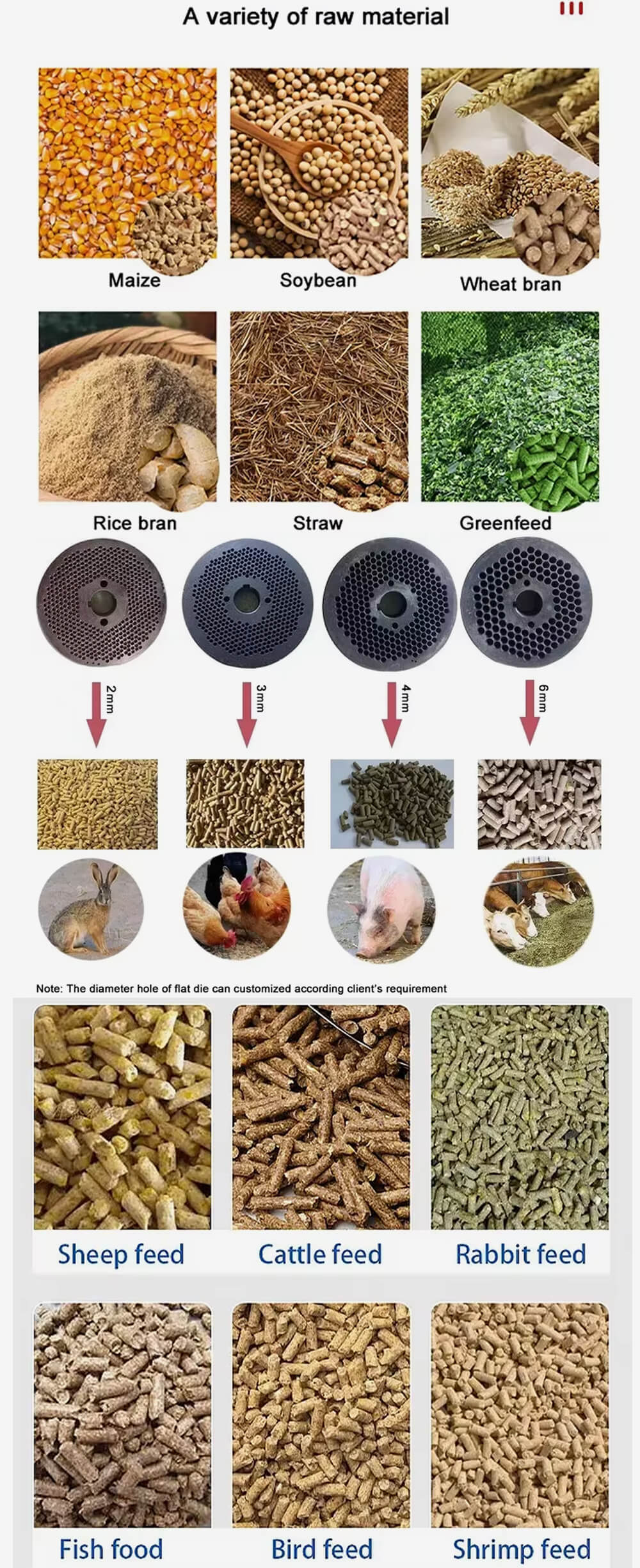

Pellet Production Line Description

Animal Feed Pellet Machine , Also known as Feed Pellet Making Machine or Bird Feed Making Machine, is used to make crushed grains, grass and other animal feed into compacted cylindrical pellets, which are used to feed animals and puppies, such as chicken, catfish, goat, cattle, rabbit, fish, dog, cat and so on. The size of the caught animal feed pellets has various options: 4, 6, 8, 10, 12mm or other customized diameter. At the same time, you can customize the flat die of the animal feed making machine with different thickness and compression ratio, so as to adapt to different materials and realize the best pelletizing result.

Pellet Production Line Each Parts Details

Hammer mill crushing machine Introduction

1)Grind the raw materials to the required size for further processing in the production of poultry pellets and livestock feed (So you can tell us your raw materials).

2) Feed hammer mill is adopted here to improve the production efficiency and make delicious poultry feed. After grinding, the diameter of the final products doing 3-5 mm, which is the optimal size for pelleting

3)Both coarse and fine grinding can be realized by adjusting the gap between the hammers and the screen.

4) Equipped with air blower, it using for collecting crushed material directly,and transport to the next machine for further processing.

Mixing machine

Mix various kinds of raw material powder evenly into a homogeneous diet.

Twin shaft efficient mixing machine is widely used in mixing powdery materials in feed industry to ensure the quality of poultry feed. * High Mixing Speed * Short Mixing Cycle * High Uniformity

Feeding Pellet Making Machine

This machine is the core of the feed pellet production line, f sourcing materials through the die holes to form compacted feed pellets, which are then cut to the specified size. The feed pellets produced by this machine have the features of rich nutrition, good palatability and high digestibility. * Low consumption, competitive price, long service life. * Driven by electric motor makes it more convenient, stable performance and environmentally friendly. * To make poultry feed pellets with different diameters, you just need to replace the pellet mill.

Cooling and Screening Machine

The feed pellets coming out of the feed pellet mill are hot and soft. Then a cooling process is required.

This cooler has significant cooling effect, excellent quality.

* Adopt the principle of counter-flow cooling to cool the pellets, such as to avoid sudden cooling, thereby preventing the surface cracking of feed pellets. * The latest design of octagonal cooling chamber, no dead angle. * Low energy consumption and easy operation.

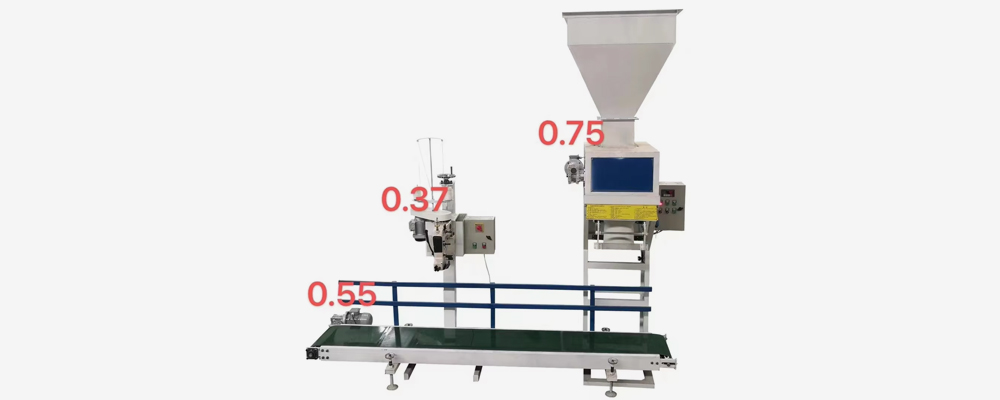

Packaging machine

The feed pellet packaging system is primarily using for packing feed pellets based on certain specifications.

This system mainly have food basket, package weighing and seam transportation three parts.

The working process of the packaging system is feeder, weighing device, folder, conveying seam.

Packaging specifications is adjustable based on detailed demand.

In addition to the main equipment mentioned above, the production line also needs other auxiliary equipment, such as conveyor belts, buffer silos, etc. Please contact us to customize a professional feed pellet production line for you.

Pellet Production Line Advantage

1. Wide range of production, we could get it into pellets from the biomass we could find now, such as wood chips, pine, bamboo, peanut shells, rice husks and straw.

2. Provide balanced nutrition and prevent animals from being picky eaters to add nutrients materials. Such as raw eggs, bone meal, nutrient solution, meat paste and other nutrients.

3. The density of pellets is 40-80% higher than that of powder, which reduces the volume of storage and transportation, and reduces the cost of storage and transportation.

4. Avoid sorting feed during packaging, transportation and feeding.

5. High temperature in the pelleting process is beneficial to eliminate salmonella in the feed (salmonella can cause gastrointestinal diseases)

6. Reduce loss and waste, the loss caused by the wind blowing the powder during feeding and feeding, and the waste caused by unclean feed during feeding.

Raw materials and application

Poultry farm machine is use for making livestock and poultry pellets. such as chicken, pig, rabbit, horse and so on.The raw material comes from agricultural waste. This machine is using for home or feeding plant in combination with other equipment.

Animal Feed Pellet Making Machine Product Parameters

| Model | NO.OF Rollers | Power (kW) | Capacity (kg/h) |

| 125 | 2 | 4 kW | 50-75 |

| 150 | 2 | 4kW-single phase 4.5kw-single phase 4.5kw-three-phase |

75-150 |

| 160 | 3 | 4.5 kW | 150-200 |

| 180 | 3 | 4.5 kW | 200-250 |

| 210 | 2 | 7.5 kW/11 kW | 250-350 |

| 230 | 3 | 15 kW | 350-450 |

| 260 | 3 | 15 kW/18.5 kW | 450-700 |

| 280 | 4 | 18.5 kW/22 kW | 750-900 |

| 300 | 4 | 22 kW | 900-1200 |

| 400A | 4 | 30 kW | 1900-2300 |

| 400B | 4 | 37 kW | 1900-2500 |

| 500 | 4 | 45 kW/55 kW | 3000-4000 |

| 600 | 4 | 75 kW | 4000-5000 |

Product packaging

Frequently asked questions

1. Can I have the prices of your products?

Sure. Please feel free to send us an email here. You will get our reply within 24 hours

2. How much will the courier freight be for the samples?

Usually, The courier freight depends on the quantity, weight and size of the carton and your area. So, we will based on detailed information to check the shipping freight of the sample.

3. How about the package?

Net weight: As customers’ requirement, so, you can tell us your requirements.

4. How does your factory treat your quality control?

Usually, our production department will strictly control the raw materials, production process, appearance, etc. during the equipment production process, so, my company always attaches great importance to quality controlling from the very beginning to the very end.

5. How about your delivery time?

Generally, it will take 7 to 30 days after receiving your advance payment. Therefore, the specific delivery time depends on the items and the quantity of your order.

-

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyRing Die Feed Production Line -

300-1000kg/h Feed Production Line

300-1000kg/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty1-2t/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty2-5t/h Animal Pellet Production Line