Main characteristics

Diesel feed pellet machine Specification

| Capacity | 100-5000 kg/h |

Other characteristics

| Applicable industries | Factory,Farm,Home use,Retail,Others | ||||||||

| Showroom location | No | ||||||||

| Origin of goods | Henan,China | ||||||||

| Weight | 75 kg | ||||||||

| Guaranteed | 1 year | ||||||||

| Key Selling Points | High performance | ||||||||

| Marketing type | New product 2020 | ||||||||

| Equipment for production Test Report | Given that | ||||||||

| Video OUTGOING-inspection | Given that | ||||||||

| Main Components Warranty | 1 year | ||||||||

| Main components | Others,Engine | ||||||||

| State | New | ||||||||

| Name | songbai | ||||||||

| Type | Granule feeding machine | ||||||||

| Product name | Diesel Feed Pellet Mill | ||||||||

| Peculiarity | Low cost high efficiency | ||||||||

| Application | Production of animal feed granules | ||||||||

| Usage | Feeding poultry | ||||||||

| Name | Diesel Pellet Making Machine | ||||||||

| Function | aniaml feed pellet making machine | ||||||||

| Raw materials | Corn,soybeans,wheat | ||||||||

| Keywords | Poultry feed processing equipment | ||||||||

| Advantage | Easy to operate,high efficiency | ||||||||

| Color | Customer demand |

Packaging and delivery

| Packaging details | Wooden case | ||||||||

| Products sold: | One item of goods | ||||||||

| Size of one package: | 100X86X86 cm | ||||||||

| One gross weight: | 68,000 kg |

Order fulfillment period

| Quantity(pCs.) | 1-1 | >1 | ||||

| Estimated time (in days) | 16 | Subject to approval | ||||

Samples

Maximum order quantity: 1 piece.

Sample price: 66 131,76 ₽ / pcs.

Made to order

Custom Emblem: Min. order : 1 pc.

Individualized packaging: Min. order : 1 pc.

Graphic settings: Min. order : 1 pc.

For more information on custom manufacturing, please send a message to the supplier

Product Parameters

| Model | NO.OF Rollers | Power (kW) | Diesel engine | Capacity(kg/h) | ||||||

| 125 | 2 | 4 kW | 8hp | 50-75 | ||||||

| 150 | 2 | 4kw-single phase 4.5kw-single phase 4.5kw-three phase |

8hp | 75-150 | ||||||

| 160 | 3 | 4.5 kW | 8hp | 150-200 | ||||||

| 180 | 3 | 4.5kw | 8hp | 200-250 | ||||||

| 210 | 2 | 7.5 kW/11 kW | 22hp | 250-350 | ||||||

| 230 | 3 | 15 kW | 32/35hp | 350-450 | ||||||

| 260 | 3 | 15 kW/18.5 kW | 35/36hp | 450-700 | ||||||

| 300 | 4 | 22 kW | 57hp | 900-1200 | ||||||

| 400 | 4 | 30 kW/37 kW | 57hp | 1900-2300 | ||||||

| 500 | 4 | 45 kW/55 kW | 133hp | 3000-4000 | ||||||

| 600 | 4 | 75 kW | 179hp | 4000-5000 | ||||||

Diesel feed pellets machine Features

|

1. Simple structure, wide adaptability, small footprint, low noise |

| 2. Higher economic benefits can got than mixed feed powder. | |

| 3. the length is adjustable, and the diameter of 3mm-6mm can be produced. Grass powder granules, pure grain granules, mixed granules, can be processed | |

| 4. Upgrade grinding wheel High quality manganese steel material, longer service life | |

| 5. nylon pulley without damage and heavy load. Bright blue body goes through six baking processes | |

| 6. increase the export, there are partitions on both sides to prevent the feed from falling |

Raw materials and final products

Applicable industries:

The feed pellet machine is suitable for livestock, poultry, aquaculture, feed factory, etc.

Applicable raw materials:

Corn, sorghum, wheat, barley, cereals are most commonly used in livestock, poultry and fish feed. Depending on the formulation, the feed can contain up to 10 different ingredients, including carbohydrates, proteins, vitamins, minerals and additives. Feed pellets can be granulated by homogenizing certain compositions proportionally.

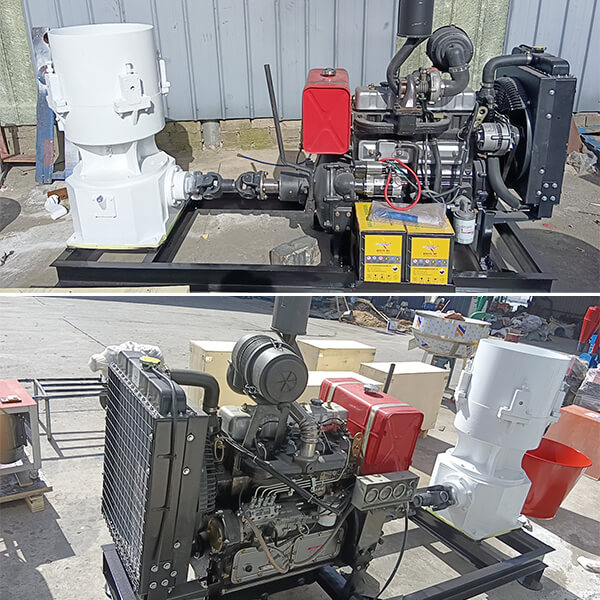

Diesel feed pellet machine Display

Diesel feed pellet machine Display

Packing and Shipping

FAQ

Q: Can l customized the machine from your company?

A: Of course you can.we can manufacture the machine based on your customsized requirement.

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;Always final inspection before shipment.

Q:What’s your Minimum Order Quantity?

A: Warmly welcome any order quantity .

Q: How long is your guarantee?

A:1 years! After this period we will definitely support you when needed,You are welcome to contact us at any time.

-

Hourly output of 30-40 kg (household use single-phase electricity is ok),

50-80 kg (main power 11 kW),

120-150 kg (main power 15 kW),

180-250 kg (main power 18.5 kW),

300-350 kg (main power 22 kW),

400-450 kg (main power 37 kW),

500-600 kg (main power 55 kW),

800-1000 kg (main power 75 kW),

1200-1500 kg (main power 90 kW).

According to the size of the breeding scale, you can choose the model that suits you.Fish Feed Extruder -

Electric Feed Pellet Machine

Electric Feed Pellet Machine -

Diesel Feed Pellet Machine

Diesel Feed Pellet Machine -

PTO pellet mill can be directly connected to the tractor when it is inconvenient to use electricity outdoors. It is movable, easy to install and operate, which make it a good choice for outdoor biomass wood pellet processing.

PTO Feed Pellet Machine