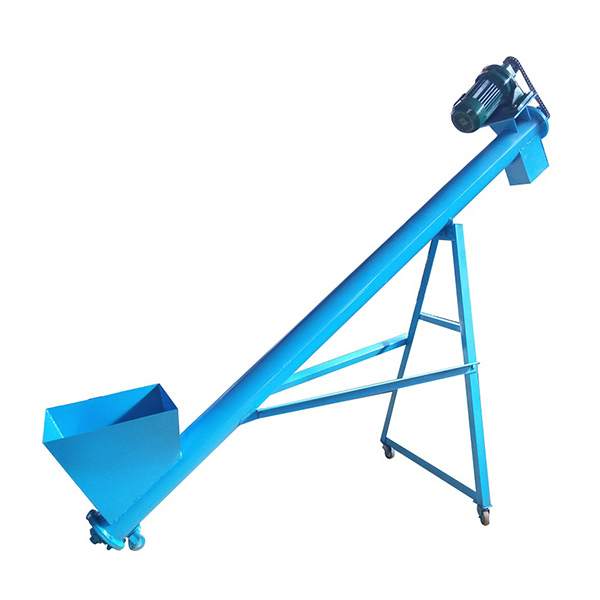

Conveyor

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty

Main characteristics

Conveyor Basic Specification

| Granule diameter (mm) | 2-12 |

| Output (kg/h) | 0-1000 kg/h |

Other characteristics

| Origin of goods | Henan,China |

| The raw materials have been processed |

Grass,Rice husk,Drying sawdust,Biomass,Straw hat,Cotton stalk |

| Guaranteed | 1 year |

| Applicable industries | Manufacturing Plant,Farm,Home Use,Retail,Other |

| Key Selling Points | High performance |

| Weight (kg) | 150 KG |

| Marketing type | New product 2019 |

| Equipment for production Test Report | Given that |

| Video OUTGOING-inspection | Given that |

| Main Components Warranty | 1 year |

| Main components | Bearing,Gear,Engine,Gearbox |

| State | New |

| Name | Songbai |

| Voltage | 380V/50HZ |

| Size(L*W*H) | 219*3 |

| Engine power (kW) | 1.5 |

| Power (kW) | 22 |

| Name | conveyor |

| Application | Make Biomass Pellets |

| Raw material | Sawdust\straw\rice Husk\wood Waste |

| Usage | Making Wood Pellets Animal Feed Pellets |

| Power Supply | Electric Engine |

| Advantage | High Performance |

| Machine type | Biomass Fuel Wood Pellet Machine |

| Material | Carbon Steel |

| Ideal moisture | 13-15% |

| Capacity | 1-1.5t/h |

Packaging and delivery

| Packaging details | Wooden box

|

| Products sold: | One item of goods |

| Size of one package: | 100X86X86 cm |

| One gross weight: | 198,000 kg |

Order fulfillment period

| Quantity(pcs.) | 1-1 | >1 |

| Estimated time (in days) | 15 | Subject to approval |

Samples

Maximum order quantity: 1 piece.

Sample price: 154 454,64 ₽ / pcs.

Made to order

Custom Emblem: Min. order : 1 pc.

Individualized packaging: Min. order : 1 pc.

Graphic settings: Min. order : 1 pc.

For more information on custom manufacturing, please send a message to the supplier

Product Description

Screw conveyor is used in many industries such as building materials, chemical engineering, coal, grain and oil, feed. It is suitable for horizontal or inclined conveying powder, granule and small block material such as grain, coal, flour, cement, chemical fertilizer and so on. It can not convey the material that is easy to metamorphose, sticky, agglomerate; The use of ambient temperature is -20 ~ 50 ℃, the temperature of the conveying material is ≤ 200 ℃.

Product Application

Why use pellet cooler and dryer?

Biomass pellets or briquettes have high moisture content above 16% and high temperature around 70-85°C, so the cooler is needed to lower the temperature of the material to 3-5°C above room temperature and for safe storage or transportation in case of mold.

Technical Parameters

| Model | ZS-3m |

| Capacity (kg/h) | 00-1000 |

| Power (kW) | 1.5 |

| Machine size | 219*3 |

| Weight (kg) | 150 |

Product Display

The working principle of a screw conveyor:

The working principle of F screw conveyor is that the rotating spiral blade pushes the materials to the screw conveyor. The acting force that does not make the material and the screw conveyor blades rotate together is the gravity of the material itself and the friction between the screw conveyor body and the material.

Packaging and Delivery

Frequently Asked Questions

1. Can I have prices for your products?

Welcome. Please feel free to send us an email here. You will get our reply within 24 hours

2. How much will be the courier freight for the samples?

The courier freight depends on the quantity, weight and size of the carton and your area.

3. How about the packing?

Net weight: As customers’ requirement.

4. How does your factory treat your quality control?

My company always attaches great importance to quality controlling from the very beginning to the very end.

5. How about your delivery time?

Generally, it will take 7 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

-

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyCooler Machine -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyVertical Cooler Machine -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyConveyor