Main characteristics

Basic Industry Specification

| Capacity | 50-500 kg/h |

Other characteristics

| Applicable industries | Manufacturing Plant,Farm,For Home Use,Others | |||||||

| Showroom location | No | |||||||

| Origin of goods | Henan,China | |||||||

| Weight | 80 kg | |||||||

| Guaranteed | 1 year | |||||||

| Key Selling Points | High performance | |||||||

| Marketing type | New product 2020 | |||||||

| Equipment for production Test Report | Given that | |||||||

| Video OUTGOING-inspection | Given that | |||||||

| Main Components Warranty | 1 year | |||||||

| Main components | Other | |||||||

| State | New | |||||||

| Name | songbai | |||||||

| Type | Kitchen faucet | |||||||

| Application | Poultry farm | |||||||

| Product name | Feed mixer | |||||||

| Usage | Feeding poultry | |||||||

| Name | Chicken Bird Feed Making Machine | |||||||

| Function | Animl feeding machine | |||||||

| Keywords | Poultry feed processing equipment | |||||||

| Advantage | Easy to operate,high efficiency | |||||||

| Engine | Electric | |||||||

| Another name | Chicken Feed Mixer | |||||||

| Capacity | 50-500 kg/h | |||||||

Packaging and delivery

| Packaging details | Customized

|

Order fulfillment period

| Quantity(pcs.) | 1-3 | >3 | |||

| Estimated time (in days) | 15 | Subject to approval | |||

Made to order

Custom Emblem: Min. order : 1 pc.

Individualized packaging: Min. order : 1 pc.

Graphic settings: Min. order : 1 pc.

For more information on custom manufacturing, please send a message to the supplier

Product Description

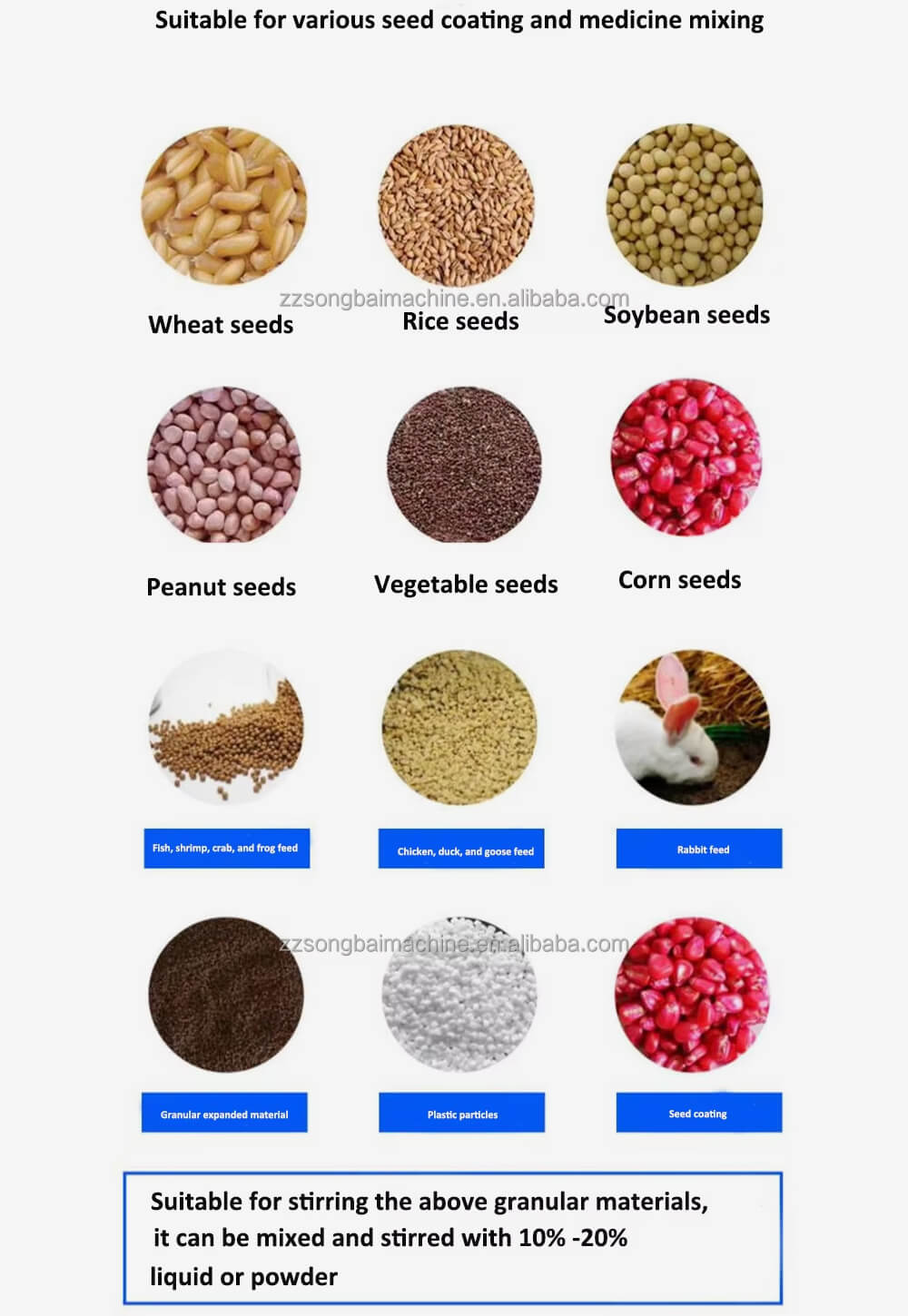

Pellet mixer

Multifunctional mixer and seed processing machine can be used for corn, wheat and mixing various powder or granule feeds, such as chicken, pig, fish, shrimp and so on. It is especially suitable for batching pellet feed, and can also mix various dry powder, powder or granule. Vertical feed mixer is a feed processing equipment specially designed for rural feeders, small feedlots and small and medium-sized feed factories.

Product Features

| Vertical FEED MIXER This is a feed processing equipment designed for rural feed, small feedlots and small and medium feed factories. |

| It can also mix food raw materials with good effect. |

| It has the advantages of simple and compact structure, one-time small investment, economical use, convenient maintenance and no need for special production sites. |

Specification

Vertical Feed Mixer Specifications

According to different feed production process , we have different models for Vertical Feed Mixer , you can check the specifications below to check which model you prefer, if you have any interest, you can contact us freely, we are glad to provide you with more professional recommendation.

| Type | Power | Rotation speed | Dimension | Inner barrel diameter X height |

Weight | ||||

| Model | (kW) | (R/min.) | (Mm) | (mm) | (Kg) | ||||

| 50 kg | 0.75 | 35/70 | 800×780×980 | 780×420 | 80 | ||||

| 75 kg | 0.75 | 35/70 | 950×900×980 | 900×420 | 90 | ||||

| 75kg | 1.5 | 35/70 | 950×900×980 | 900×420 | 95 | ||||

| 100 kg | 1.5 | 35/70 | 1050×1000×980 | 1000×420 | 100 | ||||

| 100kg | 2.2 | 35/70 | 1050×1000×980 | 1000×420 | 105 | ||||

| 150 kg | 1.5 | 35/70 | 1150×1100×980 | 1100×420 | 110 | ||||

| 150kg | 2.2 | 35/70 | 1150×1100×980 | 1100×420 | 115 | ||||

| 200 kg | 2.2 | 35/48 | 1250×1200×1080 | 1200×490 | 150 | ||||

| 200kg | 3 | 35/48 | 1250×1200×1080 | 1200×490 | 150 | ||||

| 250 kg | 4 | 35/48 | 1350×1300×1100 | 1300×490 | 200 | ||||

| 250kg | 5.5 | 35/48 | 1350×1300×1100 | 1300×490 | 220 | ||||

| 400 kg | 5.5 | 35/48 | 1450×1400×1300 | 1400×560 | 350 | ||||

| 500 kg | 7.5 | 35/48 | 1550×1500×1400 | 1500×560 | 500 | ||||

Product Application

Install and adjust:

(1) Put the machine on the horizontal ground before using the machine, make sure the machine runs stably and reliably.

(2) Check each part before use: Check the gearbox part, move it by hand to check whether it is flexible; check if

the fasteners are loose during transportation; check if the switch and power cord are damaged during transportation.

(3) Check that the power supply voltage reaches the rated voltage of the machine.

Packaging and delivery

Mini Vertical Grain Mixer Packaging & Shipping

Stainless steel feed mixer is packed in standard wooden case

Multifunctional feed seed mixer is Shipping by sea

Frequently asked questions

Pre-sale Service:

1. Design and manufature the machines according to your special needs.

2. Provide project design, process design, and purchasing program for you.

3. Help you formulate the construction scheme. We have professional team responsing for you

Sale Service:

1. Test the machine performance and help you finish the delivery.

2. Standard export package or as your demand

After-sale Service:

1. Send engineers to install them, commissioning and train operators on site.

2. Repair and maintenance if any problems occur in warranty.

3. Spare and wearing parts for free or with big discount.

4. Any feedback of the machines can be reported to us and we will try our best to support you.