Ring Die Feed Production Line

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty

Feed Pellet Production Line characteristics

Basic Industry Specification

| Capacity | 5 tons/hour |

Other characteristics

| Applicable industries | For home use,Others |

| Showroom location | No |

| Origin of goods | Henan,China |

| Weight | 500 kg |

| Guaranteed | 1 year |

| Key Selling Points | High performance |

| Marketing type | New product 2020 |

| Equipment for production Test Report | Given that |

| Video OUTGOING-inspection | Given that |

| Main Components Warranty | 1 year |

| Main components | Other |

| State | New |

| Name | songbai |

| Type | Granule feeding machine |

| Voltage | 380 V |

| Product name | Ring pellet making machine |

| Application | Production of animal feed granules |

| Usage | Feeding poultry |

| Name | Chicken Bird Feed Making Machine |

| Function | Animl feeding machine |

| Color | Customer demand |

| Keywords | Poultry feed processing equipment |

| Raw materials | Corn,soybeans,wheat |

| Capacity | 1-10TPH |

| Advantage | Easy to operate,high efficiency |

Packaging and delivery

| Packaging details | Customized |

| Products sold: | One item of goods |

| Size of one package: | 100×86×86 cm |

| One gross weight: | 198,000 kg |

Order fulfillment period

| Quantity (pcs.) | 1 – 3 | > 3 |

| Estimated time (in days) | 15 | Subject to approval |

Made to order

| Customized logo | Min. order : 1 pc. |

| Customized packaging | Min. order : 1 pc. |

| Graphic customization | Min. order : 1 pc. |

For more information on custom manufacturing, please send a message to the supplier

Feed Pellet Production Line Description

Ring Die Feed Pellet Machine

Ring Die Feed Pellet Making Machine, As we all know, small 3-10 ton feed mill adopts mature technology to produce high quality feed pellets for chicken, cattle, horse, duck, etc. with large-scale production. Based on the outstanding features of its high output, low consumption and mature technology, the 1 ton small feed mill is becoming more and more popular and has a wide market share at home and abroad. It is an ideal machine for broiler and poultry production in grain feed mill plant, livestock farm, poultry farm, individual farmers, feed production, etc.

Feed Pellet Machine Applicable raw materials and results.

1. It is mainly suitable for processing soybean, corn, wheat husk, rice crust, chopped straw, green fodder and other raw materials such as grains, oils, fish meal and beans into powder to produce high-quality pellet feed.

2. By recycling feed pellets, animals can digest and absorb feed more easily, improve feed utilization rate and reduce feed waste rate.

3. At the same time, granulated feed can also effectively reduce the influence of unwanted factors such as dust and impurities on animals.

Feeding machine for various types of animals

☑ Poultry : Chicken(Broiler chicken, Lucky chicken), Flock breeder, Duck, Poultry, Goose, Pigeon, Quail etc. (As Poultry Feed

Making Machine, Chicken Feed Making Machine)

☑ Livestock and Ruminants : Cattle, Cow, Dairy, Sheep, Goat, Horse, Alpaca, Antelope, Camel, Deer, Pig, Rabbit etc. (As Livestock

Feed Making Machine, Cattle Feed Production Line)

☑ Aquatic Animals : Fish, Herring, Carp, Mandarin Fish, Tilapia, Catfish, Yellow Catfish, Channel Catfish, Dace, Dory, Rainbow

Trout, Shrimp, Crab etc. (As Fish Feed Making Machine, Floating Fish Feed Extruder)

Feed Pellet Production Line Specification

Various Features of Animal Feed Pellet Machine

According to different pellet production, we have many models for Large Animal Feed Pellet Machine , you can check the specification below to check which model you prefer, if you have any interest, you can contact us freely, we are glad to provide you with more professional recommendation.

| Model parameters | 25D | 32D | 35D | 40D | 45D | 508D |

| Main power (kW) | 22 | 44 | 60 | 90 | 110 | 150 |

| Air conditioner power(kW) | 1.1/2.2 | 2.2/4.4 | 2.2/4.4 | 4/8 | 4/8 | 5.5/11 |

| Feeder power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Inside Dia(mm) | 250 | 320 | 350 | 400 | 450 | 508 |

| Flatbread size (mm) | 1.5-8 | 1.5-8 | 1.5-8 | 1.5-10 | 1.5-10 | 1.5-10 |

| Capacity (ton/h) | 1-2 | 2-5 | 3-7 | 4-10 | 5-12 | 8-15 |

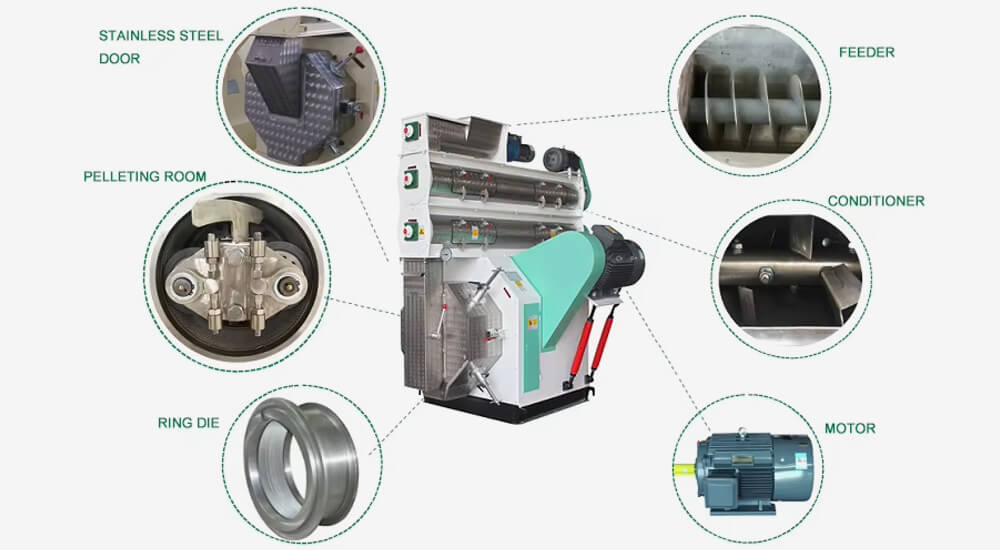

Product details

Advantages of Die Feed Pellet Machine Ring:

1. The feeder, conditioner, paddle, paddle shaft are made of 304 stainless steel, not easy to break, corrosion resistant. 2. The lining board, the oller adjusting device are made of 304 stainless steel, special roller adjusting device, high capacity. 3. Each conditioner has dorits access well for cleaning and checking 4. The door is made of stainless steel, corrosion resistant. 5. We use Danmark danfos Original Inverter, it can control the feeding speed, feeding uniformity, high capacity. 6. We use non-stop oil additive machine for the main shaft and roller shaft. It can save time and increase the service life of spare parts.

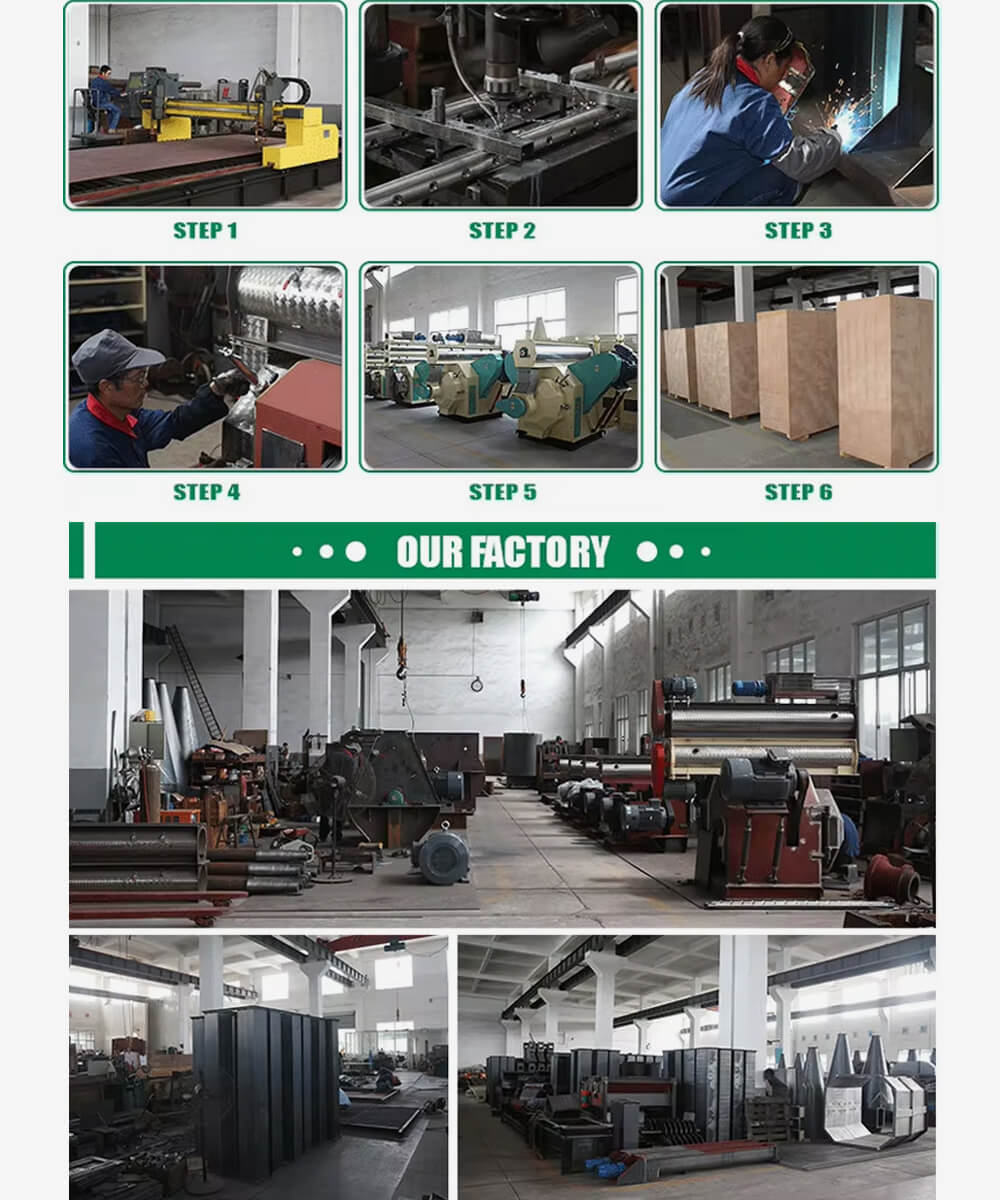

Process

Packaging and delivery

Livestock Feed Pellet Machine Packing and Shipping

Packed in standard wooden case

Shipping by sea

Frequently asked questions

1. How does your factory approach quality control?

A: Our factory has got CE, ISO9001, SGS certification. “Quality is priority”. We always pay great attention to quality control from beginning to end.

2. How long is your warranty?

A: 5 years! After this period, we will definitely support you when needed.

You can contact us at any time.

3. Will you send engineers to install the equipment?

A: Yes, we can send our engineers to make installation guide overseas.

4. If I want to buy a wood chipper, what information do you need?

A:Please tell us:

-What capacity do you want?

-The more information about your biomass materials, such as diameter/thickness, moisture, ect

-If you can send some photos to show your biomass materials, that will be better.

5.What is your motor type?

A: Electric Type Wood Pellet Machine, Diesel/Gasoline Engine Type Wood Pellet Machine,

Small Pellet Mill

-

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyRing Die Feed Production Line -

300-1000kg/h Feed Production Line

300-1000kg/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty1-2t/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty2-5t/h Animal Pellet Production Line