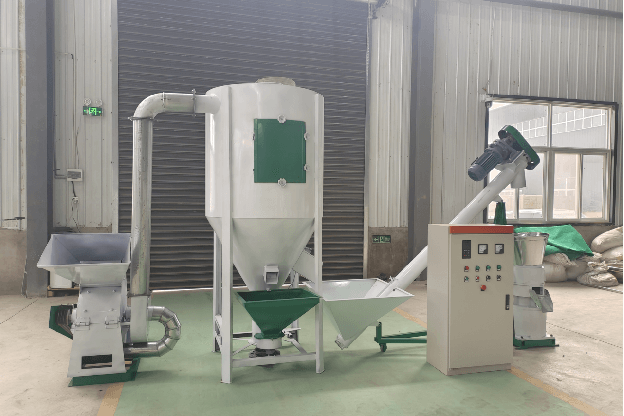

2-5t/h Animal Pellet Production Line

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty

Poultry Pellet Production Line Characteristics

Animal Pellet Production Line Basic Industry Specification

| Capacity | 5 tons/hour |

Other Characteristics of Poultry Animal Pellet Production Line

| Applicable industries | Manufacturing Plant,Food and Beverage Factory, Farm,For Home Use |

| Showroom location | Turkey,United Kingdom,Italy,France,Germany, Indonesia,Chile,Romania,Nigeria |

| Origin of goods | Henan,China |

| Weight | 6000 kg |

| Guaranteed | 1 year |

| Key Selling Points | Long service life |

| Marketing type | Hot Product 2019 |

| Equipment for production Test Report | Given that |

| Video OUTGOING-inspection | Given that |

| Main Components Warranty | 2 years |

| Main components | Engine |

| State | New |

| Name | Songbai |

| Type | Granule feeding machine |

| Voltage | 220V/380V |

| Size(L*W*H) | To order |

| Application | Make pet food |

| Product name | Animal feed manufacturing plant |

| Usage | Machine for the production of animal and bird feed |

| Function | aniaml feed pellet making machine |

| Raw materials | Wheat bran hay grass straw |

| Keywords | Poultry feed processing equipment |

| Capacity | 1-10TPH |

| The final product | Pellet products |

| Types of processing | Automatic line |

| Advantage | Easy to operate,high efficiency |

Packaging and delivery

| Packaging details | Customized  |

| Port | Qingdao\Shanghai\Tianjin |

Order fulfillment period

| Quantity (pcs.) | ‘1 – 3 | > 3 |

| Estimated time (in days) | 15 | Subject to approval |

Made to order

| Emblem to order | Min. order : 1 pc. |

| Individualized packaging | Min. order : 1 pc. |

| Graphic settings | Min. order : 1 pc. |

For more information on custom manufacturing, please send a message to the supplier

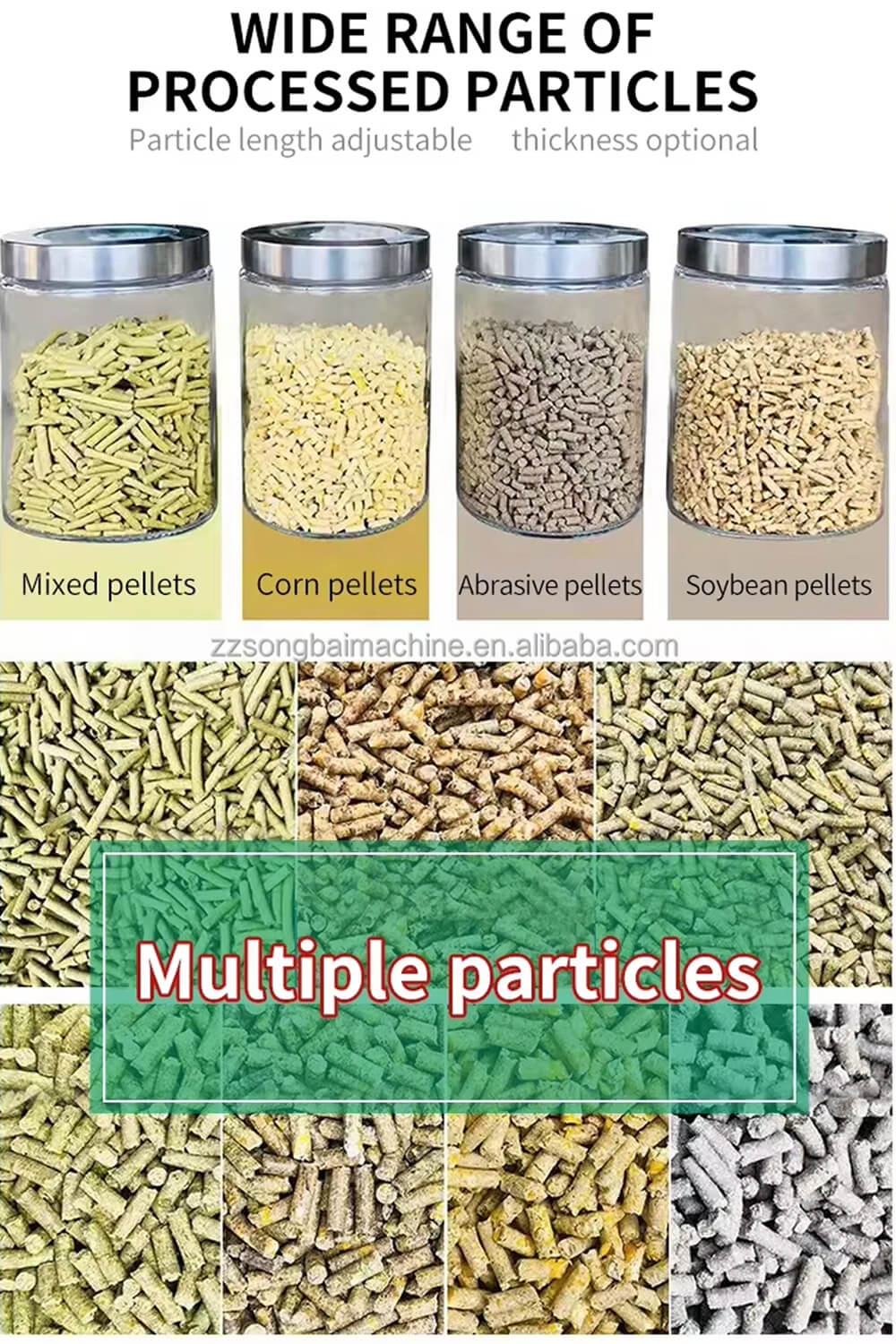

Animal Pellet Production Line Description

Animal Feed Pellet Machine , Also known as Feed Pellet Making Machine or Bird Feed Making Machine, is used to make crushed grains, grass and other animal feed into compacted cylindrical pellets, which will be used to feed animals and feathers, such as chicken, catfish, goat, cattle, rabbit, fish, dog, cat and so on. The size of the caught animal feed pellets has various options, 4, 6, 8, 10, 12mm or other customized diameter. At the same time, you can customize the flat die of the animal feed making machine with different thickness and compression ratio, so as to adapt to different materials and realize the best pelletizing result.

Raw materials and final products

(1) Classification according to feed source

Plant-based feed: including corn, soybean meal, etc. Animal feed: feed processed from animal products, such as meat and bone meal, whey powder, fish meal, etc. Microbial feed: feed fermented by microorganisms, such as silage. Mineral feed: such as rock powder, salt, copper sulfate. Special feed: such as urea, vitamins, etc.

(2) Classification according to the nutritional characteristics of feed dry matter

Feeding: Natural moisture content below 60%, Crude fiber in dry matter ≥ 18%, including rice husk, etc. It is characterized by large volume, difficult to digest, low effective energy concentration and less available nutrients.

Green feed: feed with natural water content ≥ 60%, including green, tender, soft and juicy, rich in chlorophyll and plant-based feed with high natural water content such as grass and vegetables.

Silage: It is made of silage with fresh plant feed. The advantage is to solve the problem of shortage of green feed in winter and spring, fully preserve the nutrition of green feed, expand the feed source, improve the feed quality, and eliminate pests and toxic substances at the same time.

Energy feed: feed with crude fiber <18% and crude protein <20% in dry matter, including cereals, bran, roots and tubers, and liquid energy feed. The nutritional characteristics are high-nitrogen extracts that can reach more than 70%, high effective energy, low crude protein, unbalanced amino acids, less calcium and more phosphorus, but phosphorus is usually in the form of phosphorus phytate.

Protein feed: feed with crude fiber content less than 18% in dry matter and crude protein content equal to or more than 20%. Including beans, cakes, pet food. Mineral feed: including natural and industrial synthetic feed rich in minerals such as salt, rock powder, copper sulfate, etc.

Vitamin feed: Refers to industrially synthesized or purified single or combined vitamins, but does not include natural feeds.

High in certain vitamins, such as carrots.

Additives: small and micro substances added to feed to ensure or improve feed quality, promote animal performance, ensure animal health and improve feed utilisation.

Material crusher Hammer mill

The hammer mill can crush corn stalks, straw, peanut shells, bean stalks, firewood and other combustible crop waste stalks. The useless burning of these crop stalks is avoided, the environment is well protected, and renewable energy is effectively developed. The machine has reliable performance, simple and convenient operation. The equipment produces a wide range of raw materials and can be adapted to combustible crop waste stalks such as corn stalks, straws, peanut shells, bean stalks and firewood.

| Hammer crusher is suitable for material with diameter less than 3-5 cm. | |||||

| Model | ZS-CF420 | ZS-CF500A | ZS-CF500B | ZS-CF500C | Customized Service |

| Capacity (kg/h) | 300-500 | 600-800 | 900-1000 | 1500-2000 | Large capacity |

| Power (kW) | 7.5 | 11 | 22 | 30 | |

| Machine size (cm) | 110*55*85 | 125*65*100 | 140*78*125 | 160*85*135 | |

| Weight (kg) | 350 | 450 | 750 | 900 | |

Material Mixer Mixing Machine

The feed mixer is suitable for all kinds of pastures. It can mix various nutrient fibers such as hay and silage with concentrate. Reduce the labor intensity of artificial feeding, save feeding costs and improve economic efficiency. The use of feed mixer can increase the dry matter intake of cattle, increase the production of dairy cows, improve milk quality, reduce the incidence of dairy cows, increase feed utilization, save feed costs and improve labor productivity.

| Model | Power | Capacity | Size |

| ZSM-300 | 4.5 kW | 300 kg | 1820*870*1500 mm |

| ZSM-500 | 5.5 kW | 500 kg | 2350*960*1500 mm |

| ZSM-1000 | 7.5 kW | 1000 kg | 2550*1230*1810 mm |

| ZSM-1500 | 11 kW | 1500 kg | 2800*1430*2020 mm |

| ZSM-2000 | 15 kW | 2000 kg | 3450*1650*2500 mm |

Material Feed Pellet Making Machine

Large, medium and small farms, feed processing enterprises, livestock farms, poultry farms, individual farmers and small and medium farms, farmers or large, medium and small feed processing enterprises, crush raw materials and directly press them into pellets, so that the main purpose is to make it easier for animals to eat feed and facilitate storage. All copper motor has strong power and high efficiency, durable and has good heat dissipation. The final shaft and grinding disc are made of manganese steel and hardened at high temperature.

| Model | N0.OF Rollers | Electrical power (kW) | Horse Power | Capacity (kg/h) |

| 125 | 2 | 4 kW | 8hp | 50-75 |

| 150 | 2 | 4kw-single phase 4.5kw-single phase 4.5kw-three phase |

8hp | 75-150 |

| 160 | 3 | 4.5 kW | 8hp | 150-200 |

| 180 | 3 | 4.5 kW | 8hp | 200-250 |

| 210 | 2 | 7.5 kW/11 kW | 22hp | 250-350 |

| 230 | 3 | 15 kW | 32hp/35hp | 350-450 |

| 260 | 3 | 15 kW/18.5 kW | 35hp/36hp | 450-700 |

| 280 | 4 | 18.5 kW/22 kW | 35hp/36hp | 750-900 |

| 300 | 4 | 22 kW | 57hp | 900-1200 |

| 400A | 4 | 30 kW | 57hp | 1900-2300 |

| 400B | 4 | 37 kW | 57hp | 1900-2500 |

| 500 | 4 | 45 kW/55 kW | 133hp | 3000-4000 |

| 600 | 4 | 75 kW | 179hp | 4000-5000 |

Contact us

Fully automatic pellet feeding machine production line mechanical equipment process: Raw materials → feed crusher → feed mixture → feed pellet making machine → pellet coil → pellet crushing → sieving and grading → pellet packing The above process can also add or reduce the functions of the equipment according to customer needs. Please contact our professionals to help you customize a suitable Animal Feed Pellet Machine Production Line.

-

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warrantyRing Die Feed Production Line -

300-1000kg/h Feed Production Line

300-1000kg/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty1-2t/h Feed Production Line -

1. Support customization

2. Support EXW, FOB, CIF, DDU, DDP terms

3. Support bank wire transfer, online order, PayPal, visa, Pay Later, Pix, Oxxo, Alipay, Wechat Pay

4. 3-5 days delivery

5. 1 year warranty2-5t/h Animal Pellet Production Line